HAITUO PRODUCTS

We are an enterprise specializing in the production and sales of gear measuring centers and gear measuring instruments.

HTC Series Gear Measuring Center

It is suitable for high-precision, automatic, fast and comprehensive detection of various types of involute cylindrical gears, gear cutters (hobs, shaving cutters, gear shapers), bevel gears, worm gears and other workpieces, and has the extended measurement function of camshafts, symmetrical revolving bodies and other workpieces.

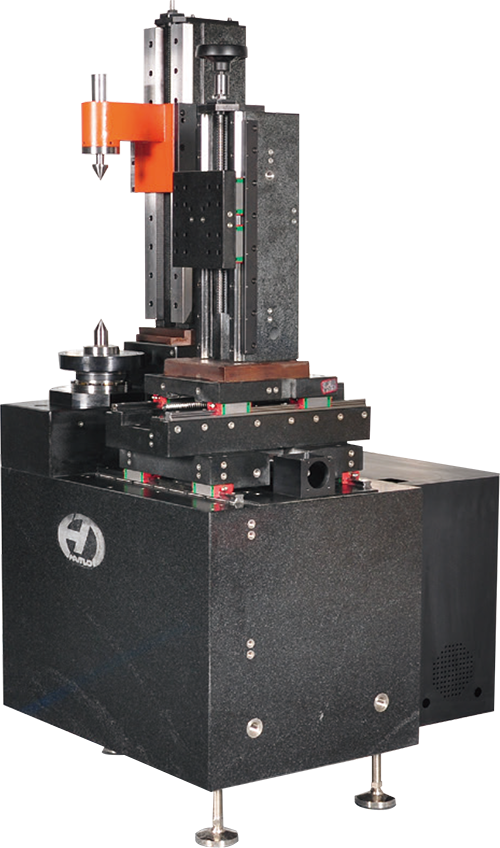

HT Series Gear Measuring Center

It is suitable for high-precision, automatic, fast and comprehensive detection of various types of involute cylindrical gears, gear cutters (hobs, shaving cutters, gear shapers), bevel gears, worm gears and other workpieces, and has the extended measurement function of camshafts, symmetrical revolving bodies and other workpieces.

HTE Series Gear Measuring Center

It is a new generation of intelligent gear measuring system developed based on computer digital control technology (CNC). It integrates the whole machine granite, imported high-precision circular guide rail, high-precision grating sensor, full closed loop servo control system, humanized measurement software and other technologies.

P-type disc tooth gear double-sided meshing instrument

The P-type disc gear double-sided meshing instrument is a high-precision gear detection instrument mainly used to evaluate the performance and quality of gears. This instrument has a double-sided meshing function, which can simultaneously detect both sides of the gear and improve work efficiency. Its unique design makes it suitable for the detection of various P-type disc teeth gears, ensuring the accuracy and reliability of the gears. In addition, the instrument is easy to operate and maintain, providing great convenience for gear quality inspection in industrial production. Its exquisite craftsmanship and outstanding performance make it highly favored in the gear manufacturing industry.

N-type internal gear double-sided meshing measuring instrument

The N-type internal gear double-sided meshing measuring instrument is a precision measuring tool specifically used to measure the double-sided meshing parameters of N-type internal gears. This instrument is advanced in design, easy to operate, and can efficiently provide accurate measurement results. It has a wide measurement range and is suitable for N-type internal gears of different specifications. In addition, the instrument also has good stability and durability, ensuring long-term measurement accuracy and stability. In industrial production, the application of N-type internal gear double-sided meshing measuring instrument can improve product quality and production efficiency, and is one of the indispensable important equipment in the manufacturing industry. This instrument is widely used in various fields such as automobiles, aviation, and machinery, making important contributions to the development of modern industry.

M micro gear double-sided meshing measuring instrument

The M micro gear double-sided meshing measuring instrument is a high-precision gear measuring device designed specifically for micro gears. This instrument adopts double-sided meshing technology to ensure accurate measurement and evaluation of gear performance. Its compact structure and convenient operation make it suitable for laboratories and production sites. This measuring instrument has high measurement accuracy and stability, and can effectively detect key parameters such as tooth profile, tooth pitch, and tooth direction of micro gears, providing reliable basis for production quality control and performance evaluation of gears. In addition, the M micro gear double-sided meshing measuring instrument also has excellent durability and reliability, which can meet the needs of various harsh working environments. Overall, this measuring instrument is an ideal choice in the field of micro gear manufacturing and testing.

Introduction to H-type gear double-sided meshing instrument

The H-type gear double-sided meshing instrument is a precision instrument used to test the double-sided meshing performance of gears. This instrument comprehensively tests the meshing performance of gears by simulating their actual working conditions, ensuring their accuracy and reliability. Its unique design, simple operation, and ability to efficiently and accurately evaluate the performance of gears. The H-type gear double-sided meshing instrument has a wide range of applications, suitable for the production, testing, and scientific research fields of various gears. The use of this instrument has greatly improved the quality and efficiency of gear production, promoting the development of the gear manufacturing industry.

DH type multi station gear double-sided meshing instrument

The DH type multi station gear double-sided meshing instrument is a precision gear detection equipment widely used in gear production, research and development, and quality control fields. This device has multi station operation and double-sided meshing detection function, which can meet the detection needs of various complex gears.

ABOUT HAITUO

We are an enterprise specializing in the production and sales of gear measuring centers and gear measuring instruments.

Qingdao Haituo Precision Instrument Co., Ltd., founded in 2010 and located in Laoshan District, Qingdao, is an enterprise specializing in the production and sales of gear measuring centers and gear measuring instruments. It integrates the top gear measuring technologies in China and is based on high-precision mechanical quality and absolutely stable systems. Now Haituo is actively seeking international cooperation and is determined to make Haituo measuring instrument the standard of measuring instrument.

SINCE TO

Senior employees

Undertake major projects

Patent qualification

ADVANTAGES

Free development of non-standard software

The software has the function of eccentric correction, which is mainly a measurement method for workpieces with heavy gears that are difficult to move or have no central hole.

CNC mode

Our company adopts a true full closed-loop control mode (closed-loop in motion controller), which is different from closed-loop in motor driver.

Using analog speed loop

A sine wave is a continuous current that reflects smooth motion in motion, and the screw also rotates continuously. That is, the motor can travel any distance it wants.

Pulse position loop

It is a type of pulse control, which is a discontinuous current reflected in motion, and the screw also rotates in a discontinuous manner, forming a serrated motion.

LAST NEWS

LAST NEWS